Grauer and Weil Designs, Manufactures, and Installs efficient material handling systems or Material Handling Systems to suit a variety of Surface Finishing Plants.

There are numerous variants of motorised transport systems. Different types of material handling systems or transport wagons are available to suit specific requirements. These facilitate hoist and traverse movement of Racks and Barrels and can have special functions like dunking, tilting, barrel rotation and drip trays for reduced solution carry-overs.

Shivam Automations has designed and manufactured a wide range of material handling systems capable of operating with traverse speeds of up to 50m/min, pay loads of up to 8 tons and span of up to 14 meters. All our systems are equipped with Laser/ Linear guided positioning systems to precisely align the wagon with process tanks.

Design of a Material Handling system is dependent on:

Based on the type of plant, following are the different type of Material Handling Systems we manufacture:

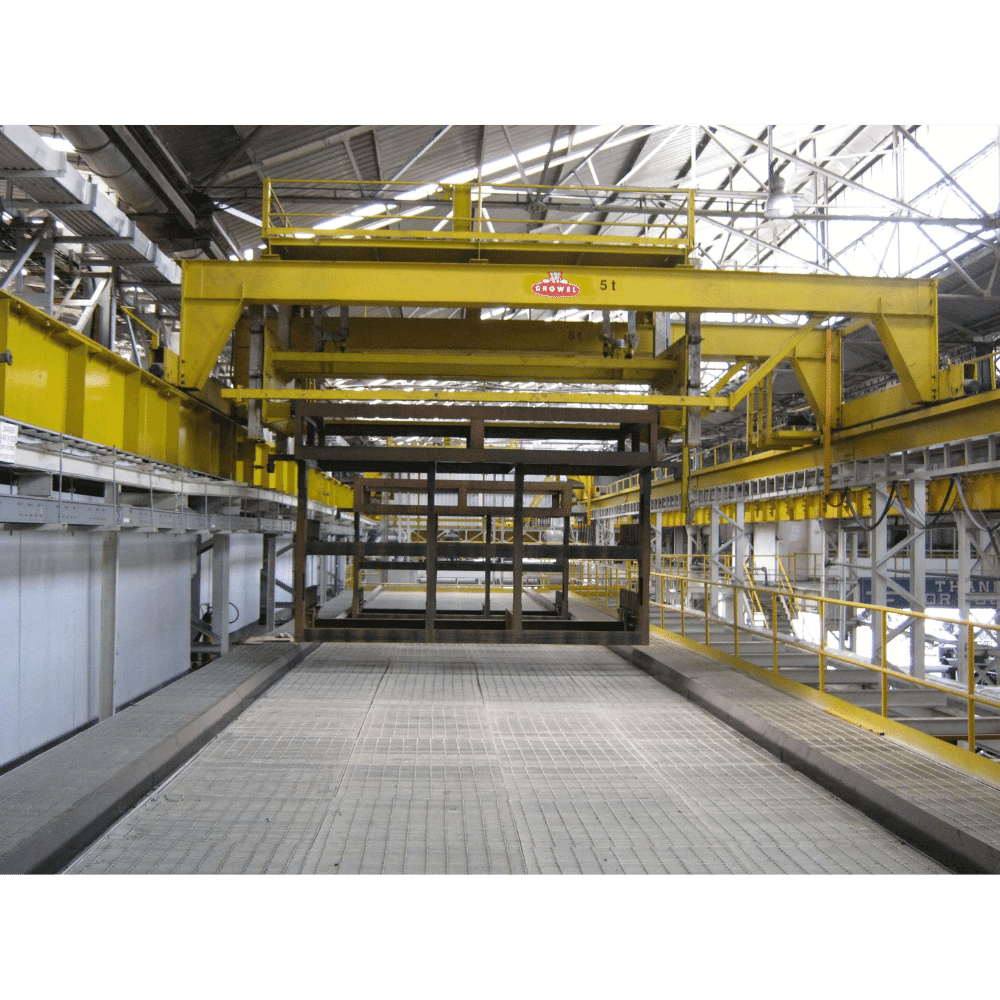

These work on an overhead track system and allow for the transportation of heavy payloads. The overhead track system comprises of runway, guide wheels, catenary cable track, etc. The track system can either be mounted directly on the ceiling of the building or on a self-supporting floor mounted portal structure depending upon the space availability.

Skid type transporters are available in different sizes. It is ideal for construction of light weight applications. The transporter has a bridge type design, providing maximum stability during movement and accurate positioning. Due to its independent modular design, it is possible to assemble such systems at our works and offer inspection of dry runs before dispatch.

The transport wagon, guided on a laterally arranged track, is mounted on a self-supporting floor structure above tank level, incorporating the busbars and the cables ducts for loads up to 150kg.