Shivam Automations Manufactures the following Anodizing Plants:

- Home

- ANODIZING

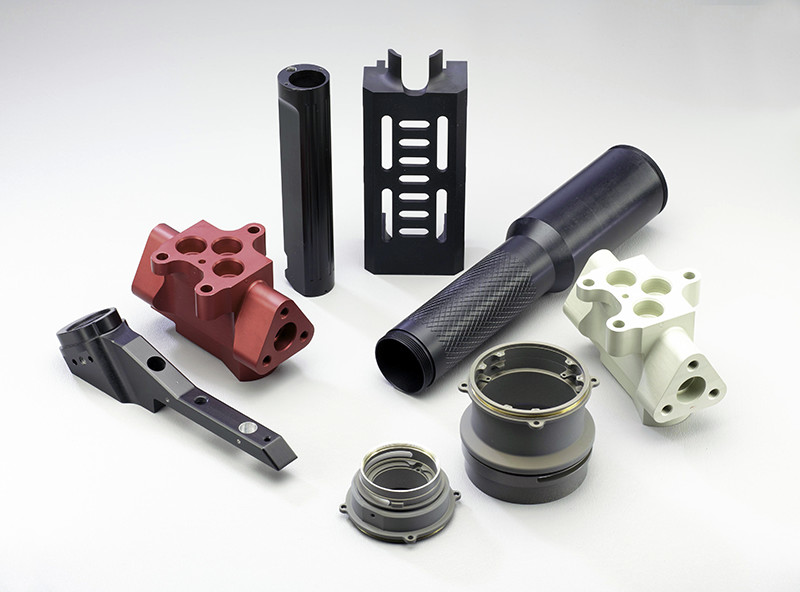

Anodizing or Anodic Oxidation is an electrochemical process of Oxidation by which it forms a protective layer of Aluminium Oxide on the Surface of the components. It is considerably used in the Aerospace Industry to provide a protective and corrosion resistant film on Aluminium. Anodizing provides special protection against moisture and dust, increases the hardness of components, provides resistance to abrasion, wear and corrosion, and gives an aesthetic finish to the part.

Anodizing is widely used for various applications based on its properties as stated below:

Anodizing is employed for components which require protection and high resistance to corrosion. Anodic coating protects the underlying metal by serving as a barrier to corrosive agents. Aerospace and Defence Equipment are areas of application.

Anodizing provides an attractive, decorative, and protective finish for a wide range of Aluminium components. Depending upon the initial surface condition a Bright, Semi-bright or Matte finish can be achieved. Anodizing films can also be dyed to provide a variety of attractive colours.

Window frames, door fittings are examples of components which are generally Anodized. It provides the requisite corrosion protection and can withstand outdoor conditions. Most of the aluminium used in architectural applications is anodized.

Anodizing components helps improve its bond strength and durability. This property is widely employed in Aerospace industry to manufacture airframe structures.

Hard Anodizing is employed for various engineering applications which require a thicker and harder anodic film compared to normal anodizing process. Hard anodizing at minus temperatures is also applied to cookers.

1. Sulphuric acid anodizing with Electro colouring/Dyes. 2. Hard anodizing 3. Boric plus sulphuric acid anodizing 4. Tartaric plus sulphuric acid anodizing 5. Chromic acid anodizing.

Chromating is a chrome conversion dip process on aluminum usually employed in automobile and aerospace components. It has an application as a pre-treatment before powder coating.