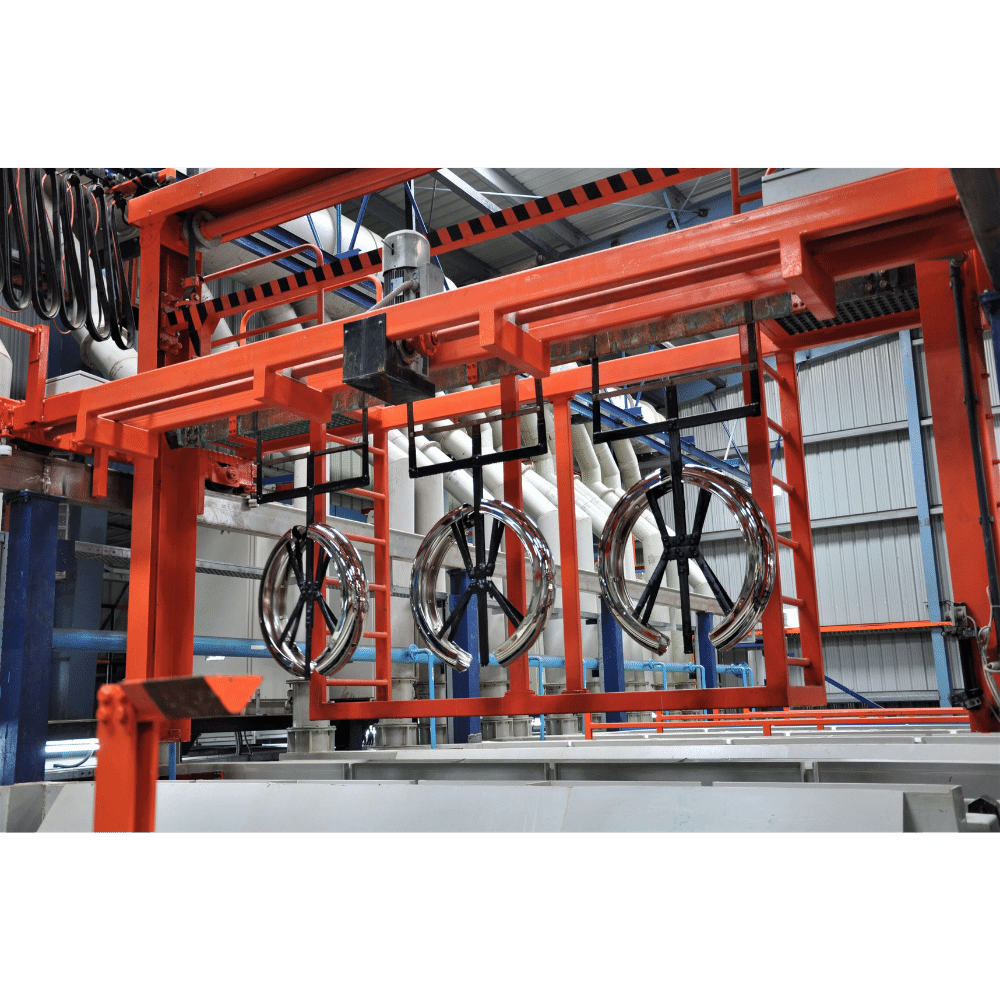

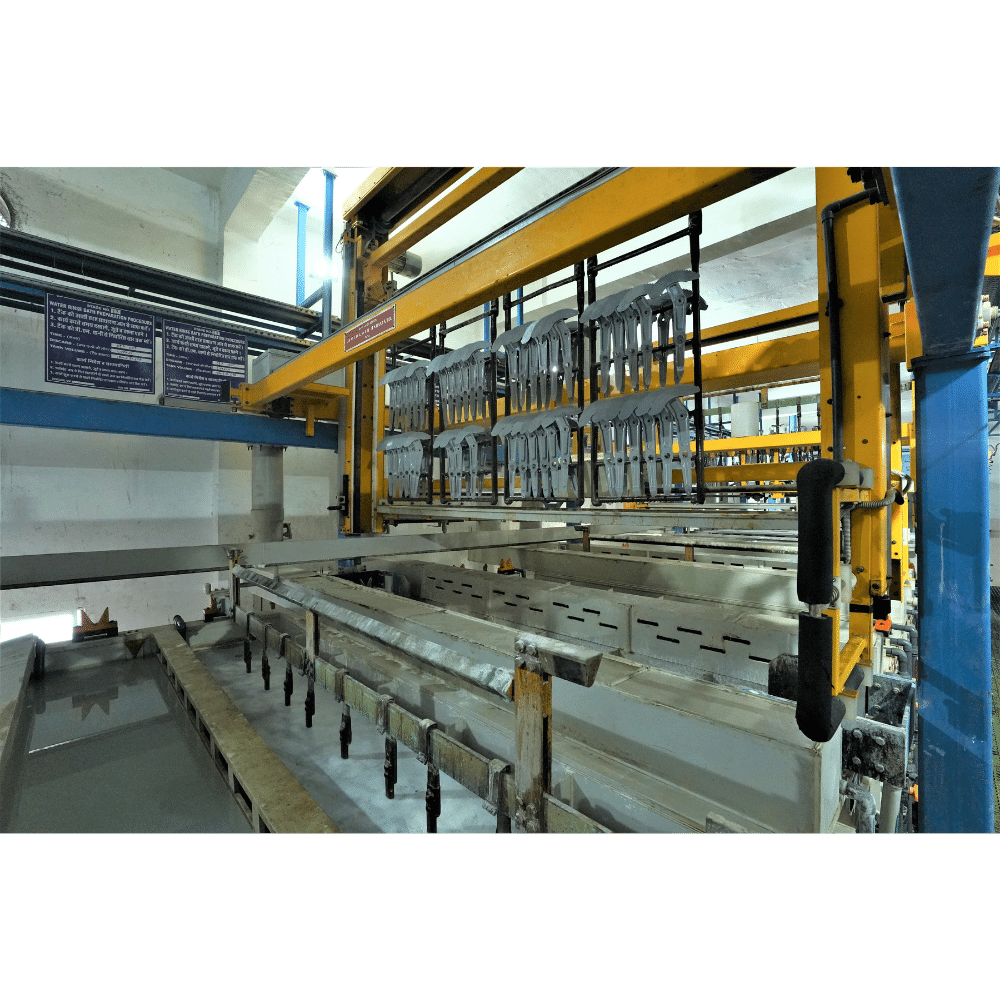

RACK PLATING PLANT

SHIVAM AUTOMATIONS conceptualizes, designs, manufactures, supplies, and installs state of the art Rack plating plants to suit various processes.

In Rack plating the component is fixed to a frame or jig called the Rack. The Rack, and hence the process tank, can be designed in various sizes depending on the type of component to be finished and the volume of production.

Our plants are highly customizable depending on the customers requirement.

Application

Rack plating plants are beneficial when the components undergoing surface finishing are complex in shape or big in size.

The rack or the jig serves two main purposes:

Secure the component throughout the surface finishing process.

Helps in passing DC current and maintaining electrical contact.

Apart from this the Rack also helps in the alignment of the component to achieve the correct plating thickness, coat quality and drainage of excess solution.

PROCESS

Suitable for below mentioned processes:

Electroplating

Anodizing

Pickling

Phosphating

ADVANTAGES WITH Shivam Automations

Diverse experience – Supplying plating lines since 1965, 800+ plants commissioned

One stop solution – for all spares, consumables, and chemical requirements

ISO 9001:2015 Certified

Benefits

Ability to handle various finishes

with a range of components in the same plant.

Enhanced Shivam Automations Automation Features

Contemporary Material Handling System

Integrated PLC controlled Fume Extraction System

Comprehensive features for Man and Machine safety

Extremely Maintenance-Friendly Design

Designed to optimize Water Consumption

Plants available with Automatic, Semi-Automatic and Manual options

Automation

Automation is greatly preferred in bulk plating operations, predominantly for the following reasons:

Consistency

Reduction in labour costs

Elimination of human error

Elimination of human error

Regulated inputs

Effective control for production

Versatility and Traceability

Automation Features:

Automation Features:

Automatic current and temperature control as per process requirement.

Auto level and conductivity control

Auto dosing as per ampere-hour consumption/as per area processed

Production and event/alarm data recording

Online process monitoring

Event warning by SMS/Email

Voice Alarm

Bar Scanner for parts identification

Data Logging (SCADA) is an integral part of automation and has become a necessary tool for all plating plants. Shivam Automations’s sophisticated SCADA system with enhanced features are supplied with all its surface finishing plants. Data Logging helps in:

Online monitoring of status of Material Handling, Tanks and Equipment

Generating an immediate alarm in case of abnormalities in the process conditions

Accurate control of process parameters like temperature, current etc

Generation of reports for Day/Shift/Load wise production

Recording of all errors and abnormalities

Unlimited LAN access for control and monitoring of plant with multilevel password protection

Generation of Trend screens for all process parameters in real time

Maintaining alertness for all predefined mechanical, electrical, and chemical parameters

Additional Features

Fume exhaust system

Dosing system

Metal recovery system

Effluent Treatment Plant